Hydraulic breaker chisels are essential tools for breaking hard materials such as concrete, asphalt, and rock. The hydraulic breaker chisels come in various sizes and shapes to suit different applications. However, in some cases, for some breaker standard chisels may not meet specific requirements and customization is required. Custom hydraulic breakers chisels can provide tailor-made solutions to meet the unique needs of a specific job. In this article, we will explore the process of customizing a hydraulic breaker chisel and how to measure the chisel size for customization.

When customizing a hydraulic breaker chisel, the first step is to evaluate the specific requirements of the job. This may include the type of material being broken, the size of the work area, and any other unique factors that may affect the performance of the chisel. Once the requirements are determined, the next step is to measure the chisel size to ensure the custom tool will fit the hydraulic breaker.

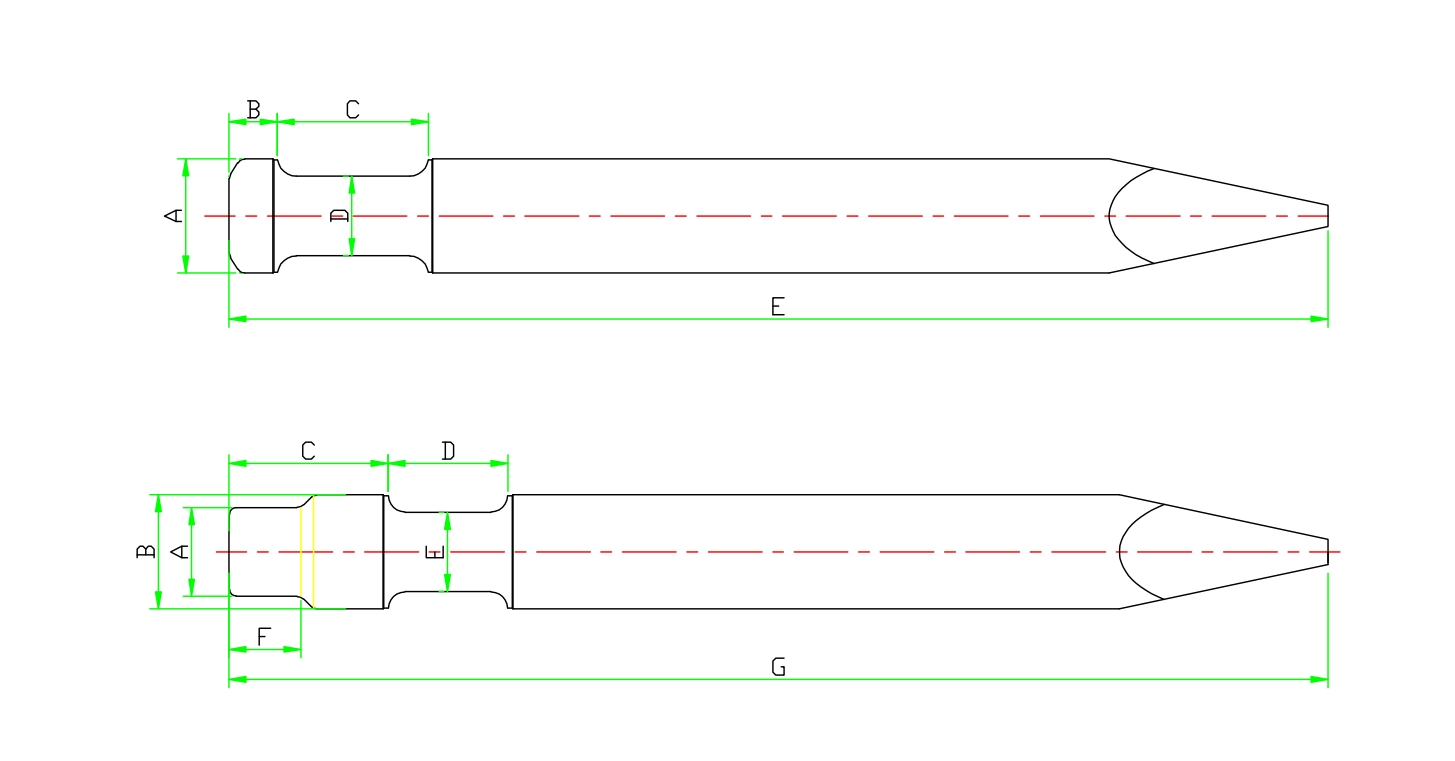

Measuring the size of a hydraulic breaker chisel is a simple process that requires a few simple tools. The most important measurements are the diameter and length of the chisel. To measure the diameter, use calipers or a tape measure to determine the width of the chisel at its widest point. This measurement will help ensure that the custom chisel fits securely into the hydraulic breaker. Next, measure the length of the chisel from tip to base. This measurement is critical to determining the overall dimensions of the custom chisel and ensuring it is compatible with the hydraulic breaker.

Once the chisel dimensions are accurately measured, the customization process can begin. There are several ways to customize a hydraulic breaking chisel, depending on the specific requirements of the job. One common approach is to modify the shape of the chisel to better fit the material being broken. For example, if the job involves cutting through particularly hard rock, the chisel may need to be customized with a sharper or tapered tip to increase its penetration capabilities.

Another aspect of customization is the material used to make the chisel. Different materials offer different levels of durability and performance, so choosing the right material is crucial to ensuring your custom chisel will meet the requirements of the job.

When customizing a hydraulic breaker, it’s important to work with a reputable manufacturer or supplier, for example - DNG Chisel, with more than 10 years production experience, which can provide expert guidance on the best customization options based on the specific requirements of the job. In addition, the necessary expertise and equipment to ensure that custom chisels meet the highest quality standards is also very important.

Customizing a hydraulic breaker chisel is a valuable process that can provide customized solutions to meet the unique needs of different jobs. By accurately measuring your chisel dimensions and working with a reputable manufacturer or supplier like us, you can create a custom chisel with optimal performance and durability, ultimately increasing efficiency and productivity.

Post time: Jul-26-2024