The correct selection and using of a hydraulic breaker chisel/drill rods is really essential for maximizing the tools performance and extending its service life. Below are some tips for your reference.

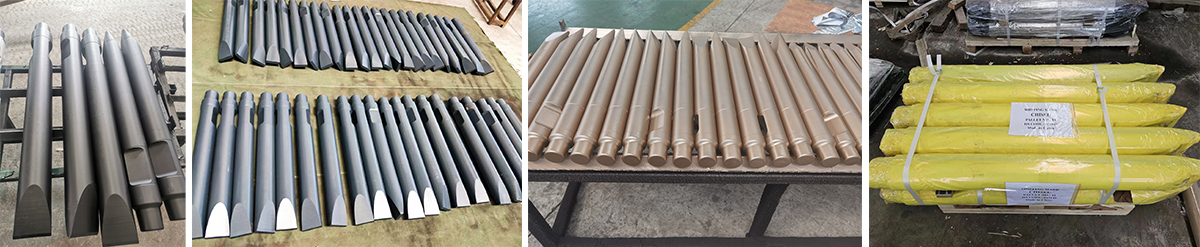

a. Different chisel type suitable for varies operating environment, eg.

Blunt Tool Chisel (Used for impact breaking, for example, secondary breaking and scaling in mines and tunnel).

Wedge Chisel, eg. H-wedge type & V-wedge type(Suitable for cutting, trenching and benching in soft and neutral layered rocks, which can give higher wear rates and stress levels in the retainer flat areas of the tools).

Moil point Chisel (Suitable for the working where penetrative breaking is required) etc.

b. Make sure the hydraulic breaker chisel tools matching hammer, eg.

SB20 SB30 SB50 SB60 chisel for SOOSAN

F6 F9 F22 chisel for FURUKAWA etc.

c. Considering different application to select appropriate material eg. 40Cr 42CrMo 46A 48A etc. Chisels made of hard and tough material is more suitable for breaking hard rock, while the other material may be more suitable for concrete or softer materials. Also different chisel size, length&diameter, should be used for varies application. This can protect chisels better.

d. Chisels/steel drill rod/ maintenance and proper use can achieve the maximum performance of chisel and extend the service life. The maintenance of chisel is simple, but regular inspect can keep it in optimum condition, including regular cleaning, lubrication, and replacement etc. The better training of operators for knowing the best practices is necessary for the correct use of hydraulic breaker chisel. Keep the direction of chisel and the working surface be vertical. If not, the chisel may slip during hitting. After adjusting the working angle of chisel, then select the impact spot of working material to crush under stable conditions. If the first hitting operation can not break the material, don’t strike in same position more than 10 seconds, which will increase the temperature of chisel, cause damage to chisel. The correct operation is moving hammer to a new working position and crush again. Another important tip to operate is following the instructions of hydraulic breaker manufacturer, eg. proper breaker operating pressure, oil flow rate and impact rate/energy, avoid causing premature wear and potential damage.

Post time: Apr-16-2024