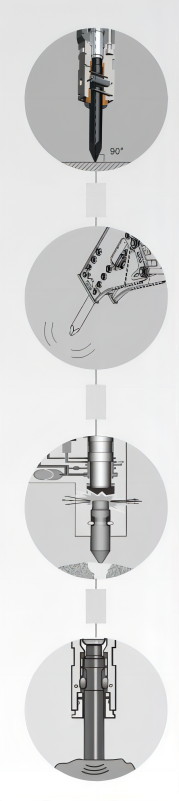

Working Angle

It is very important to keep the correct working angle of 90° to the working surface. If not, the tool life will be shorted, and take bad results on the equipment, such as high contact pressure between tool and bushings, wear away the surfaces, broken the tools.

Lubrication

Lubrication of the tool/bushing regularly is necessary, and please use the correct quality high temperature/high pressure grease. This greases can protect the tools on the extreme contact pressures generated by an incorrect working angle, leverage and excessive bending etc.

Blank Firing

When the tool is not or only partially in contact with the work surface, use the hammer will cause heavy wear and damage to the parts. Because the tool being fired down on to the retainer pin, will destroy the upper retainer flat radius area and the retaining pin itself.

Tools should be examined regularly, such as every 30-50 hours, and ground out the damage area. Also check the tool in this opportunity and see if the tool bushings for wear and damage or not, then replacement or reconditioning as necessary.

Overheating

Avoid to strike in same spot more than 10 – 15 seconds. Too much time hitting may lead to excessive heat build-up at the working, and may cause the damage as “mushrooming” shape.

Reconditioning

Normally, the chisel no need reconditioning, but if lost the shape on the working end can cause high stresses throughout the tool and hammer. Reconditioning by milling or turning is recommended. Welding or flame cutting is not recommended.